Instantly cut out plastic from your packaging with 13 Eco-friendly packaging ideas

Many websites are there on packaging topic which describes the eco-friendly options in place of plastic packaging. But the implementation is complicated in terms of marketing approach, customer understanding, stability of the product, and transport effectiveness.

How to use less plastic? Main Concern

As we know, plastic is a burden on the earth, and we have a light strategy to handle this futuristic pandemic. We(Packaging Technologist, Companies, and User) all consider this issue will eventually eliminate the problems from the world, and automatically, all packaging will set in the eco-friendly default program. But, we all knew the reality and what will going to be occur.

Last decade, we concentrated on sustainability and never focused on calculating the sustainability impression on the earth. Sustainability never says for paper usage over plastic, but it says those with less carbon emission during manufacturing can be best for the pack. So, give you instant eco-friendly alternatives (Paper & Green) to implement for your package in place of plastic-based packaging.

We, packaging guys, know about the implementation process for the packaging item for their product. So, today I have introduced the 13nos of packaging items; many of them counted as auxiliary packaging, which can easily replace with paper and paper-based products.

This article explains the simple hacks of replacing plastic with paper-based packaging for our futuristic environmental goal.

Before explaining, Let’s understand the benefits of Eco-Friendly Packaging?

Eco-friendly packaging has a very definite impact on the overall ecosystem, your company, and your consumers. Green packaging can even improve your business be in the green financially too! Here’s a closer look at how eco-friendly packaging can benefit both the planet and your bottom line.

- It is easy to dispose of or reused.

- It’s highly biodegradable and recyclable,

- The production of materials that make eco-friendly packaging

- The raw material is organic and natural.

- Green packaging uses less material than traditional packaging, making it another win for the environment.

- Green packaging is versatile – you can use it in almost every industry.

Here is the list of eco-friendly packaging ideas; how to reduce plastic consumption in our packaging profile?

No. #1 Removal of Shrink Sleeve

Shrink Sleeve uses as labels are full-color 360degree printed labels that use heat in the application process to confirm the label to the shape & size of the product is applied. These shrink sleeve labels are printed on either PET or PVC film material. The strength of shrink sleeves makes them well-suited for products that encounter moisture or friction. The shrink sleeve label is using on the carbonated PET bottle, perfumes bottles, CANS, and drinking water label.

Instant Alternative of Shrink sleeve label is Paper labels with lacquered coats have the same benefits as the shrink sleeve. Generally, the packaging technologist uses the shrink sleeve label for the deep freeze items so that the image won’t change. But many paper companies such as UPM and Avery Dennison have eco-friendly paper options for the deep freeze product label. This category can also be easily replaced with a paper label but only need to be in line with the marketing trend. Labeltronix, Anaheim, Calif., recently introduced a new label material called Arctic Shield that delivers a sophisticated look and does well with flexographic or digital offset printing, it says. It can be on uncoated, waterproof, and chill-proof white paper built to hold wetness and freezing temperatures, it adds.

No. #2 Removal of Plastic Tape (BOPP)

The commonly used adhesive packing tapes used in sealing medium to heavy-duty carton sealing, shipping, inventory management, and logistics industries are BOPP tapes. BOPP is abbreviated as Biaxially Oriented Polypropylene. The application of Polypropylene in producing adhesive tapes is because of its unique features and properties. It is a thermoplastic polymer malleable at certain specific temperatures and returns to the solid form when cooled. The BOPP is mainly using for closing the flaps of corrugated fiberboard and mono cartons.

Instant Alternative of BOPP tape – Kraft Paper Tape comes with different grades, while the adhesion value and thickness of the paper have to be adjusted according to application. Kraft Paper Tape has a natural rubber-based adhesive system that makes an excellent bond to most packing products and surfaces. It’s rigid backing intact strong under moist conditions, and outdoor weathering is good. It is accepted and approved packing tape by the Postal Service and UPS. Its particular applications incorporate box sealing, packing, freezer tape, and wood-line masking.

No. #3 Removal of PP, Vinyl, or PET labels(BOPP)

Polypropylene (PP) refers to the material from which these labels are made. It is more durable than most labels and is tear-proof and waterproof. Polypropylene labels are ideal for a wide range of retail packaging uses, such as hair care, cosmetics, or pharmaceutical products. The main feature for choosing the material is squeezing back property without wrinkles, such as when the consumer squeeze the pack for the product comes out, the wrinkles on the labels won’t occur.

Instant Alternative of PP, Vinyl, or PET labels – Metalized Paper labels gives the same benefits as plastic labels. The wrinkles issues can be short out with the metalizes label with paperback. We can have pre-printing to the packaging item itself with the thermal transfer printing and can use the screen printing. Additionally, the lacquered coat can makes it a barrier to water and moisture.

No. #4 Removal of Lamination

Lamination is used for an additional layer on the substrate. Typically on the paper substrate or fiberboards, providing a good-looking and resistant surface for use as packaging items.

Instant Alternative of Lamination – Coating is a non-lamination value-added service that is performed after printing. A coating is a chemical treatment applied to a paper or paperboard to achieve characteristics that would not have been possible otherwise. Coatings can create a food-grade barrier, allow printing on an otherwise unprintable surface, prevent curling, and more. Coating always is a cost-effective option for the paper-based product.

No. #5 Removal of Plastic strapping

Strapping is a commonly used tertiary item, unitization, and bundling in the packaging industry. There are multiple types of strapping products available, as well as many application types. Still, strapping is primarily used in environments such as Bundling together for handling and shipping: newspapers, pipe, lumber, concrete block, etc. It attaches items to pallets, skids, and crates and reinforces multiple packs, containers, and corrugated boxes, such as Gaylord.

Instant Alternative of Plastic strapping – Paper Strapping is an utterly recyclable alternative to polypropylene plastic strapping. It is designed for use with automatic or semi-automatic machine operations. The strapping requires less energy to apply than its plastic counterparts. With Paper Strapping requiring less energy to apply and being made from 100% recyclable material, you get a packaging solution with all of the benefits of polypropylene plastic strapping but environmentally friendly and with a reduction in operational costs.

No. #6 Removal of Stretch Wrap

Stretch wrap or stretch film is a highly stretchable plastic film wrapped around items. The elastic recovery keeps things tightly bound. It is regularly using to unitize pallet loads but also may be used for bundling smaller items.

Instant Alternative of Stretch wrap – Mondi’s has made a new lightweight paper grade, Advantage StretchWrap, which can wrap and resist puncture when covering pallets to guard goods during transportation. Currently, our industry is using multi-layer plastic, which is difficult to recycle and is presently used for pallet wrapping, switching to a responsibly sourced renewable material, the new market standard.

Advantage StretchWrap (patent-pending) is a brand with an outstanding stretch of up to 11% and high-tensile strength. The paper has worked in the low grammage of 70 gsm; it makes it a robust and lightweight wrapping solution for goods transit on pallets. It has been examined and claimed the compression holding force test according to EUMOS standard, which means that the pallets can be safely transported.

No. #7 Removal of Shrink Bundler

Shrink bundling, or multi-packaging, is the process of making one bundle, or “pack,” out of multiple items or products. A shrink bundle may include products that are unsupported or placed in a tray or on a pad. The pack is then sleeved in a layer of Low-Density Polyethylene film (LDPE) and conveyed through a heated shrink tunnel – shrinking the film tightly around the product, creating a pack.

Instant Alternative of Shrink Bundler – KHS – Innovated Paper Bundler The KHS has innovated a new step to add bundler paper wrap in their portfolio. And it was tried-and-tested Innopack Kisters tray packers, the system’s supplier allows to wrap the cans of food and beverage in the paper. It is an alternative to shrink bundler wrap and also for wrap-around cartons for the drinks CANS.

No. #8 Removal of Blister Pack

Blister packaging is widely used across the pharmaceutical industry as a unit-dose packaging solution that helps people take the correct amount of medication at the right time. Blister packaging is made using several types of rugged polymers, including:

a. Polyethylene terephthalate (PET)

b. Polyvinyl chloride (PVC)

c. Polyvinylidene chloride (PVDC)

d. Polychlorotrifluoroethylene (PCTFE)

e Cyclic olefin polymers (COP).

Blister packaging is manufactured from a plastic sheet that is thermoformed to create cups or blisters that hold a product in place. The packaging typically has a paperboard backing or a lidding seal of aluminum foil or plastic film.

Instant Alternative of Blister Pack – EnviroSense PaperBlister™ first of its kind for all-paper retail blister package. The new EnviroSense PaperBlister™ provides an alternative to the more traditional thermoformed plastic blister package found prominently in retail outlets worldwide. This new mono-material package is further evidence of our commitment to developing more sustainable options for our customers and consumers alike. This technology enables us to produce a paper-based option that many shoppers and brands are looking for without sacrificing merchandising benefits. For pharmaceuticals, the product can pack in paper-based with aluminum layered with all the benefits of the blister.

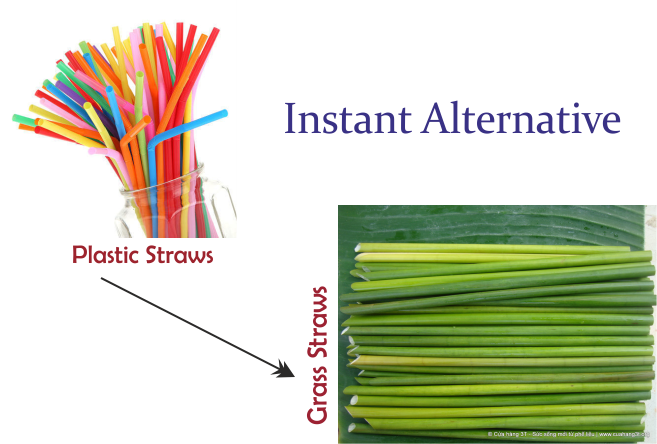

No. #9 Removal of Plastic Straw

The most common form of drinking straw is made of the thermoplastic polymer Polypropylene. This plastic is known for its durability, lightness, and ability to be manufactured cheaply. Other plastic polymers that exhibit these traits include polyethylene (PE) and polyvinyl chloride (PVC).

Instant Alternative of Plastic straw – Paper Straw, Grass Straw, Wheat Stubble straw, Coconut Straw & Jute Straw

Many innovative eco friendly packaging ideas is readily available in the market, but we just have to utilized the available resources. Below links has the complete details of the innovation eco friendly packaging examples.

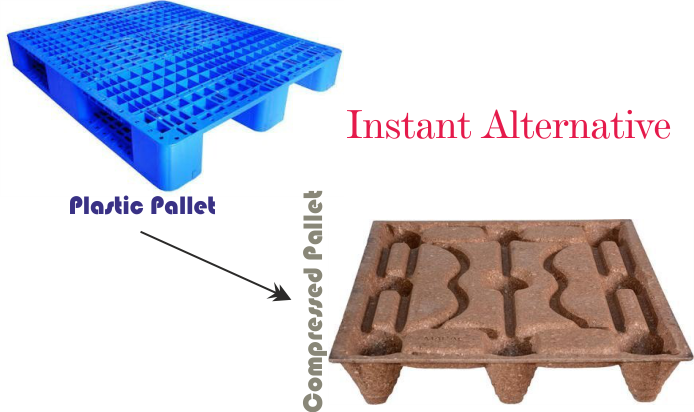

No. #10 Removal of Plastic Pallet

Plastic Pallets – A pallet is a horizontal platform typically affixed to a superstructure and a bottom deck. It allows it to be lifted and moved by material handling equipment such as lift trucks and conveyors and be placed in appropriate storage systems and transport vehicles. The pallet provides the base for assembling, storing, handling, and transporting materials and products. Additionally, a pallet offers protection to the product on it. Generally, the plastic pallet is used for internal transfer due to its effectiveness in the internal transfer and efficacy. Plastic pallets are prized for several reasons, including durability, ease of cleaning, exemption from ISPM 15 requirements, and other benefits.

Instant Alternative of Plastic pallet – Paper pallets are popular due to their lightweight, cleanliness, ISPM 15 exemption, and ease of recycling. Wood composite pallets are also ISPM 15 exempt, providing a stiff, competitively priced product that can be readily recycled and typically nestable to improve cube utilization in transport and storage. Metal pallets also have a presence, especially in applications where pallet strength and durability are requirements.

No. #11 Removal of Woven Bag

PP woven bags are bags made of PP plastic in the woven method. Woven or weaving is a method by many threads or tapes incorporated in two directions (warp and weft) to form a fabric for plastic industry needs. Polypropylene (PP) is one kind of thermoplastic resin material produced by the polymerization of propylene.

Instant Alternative of a woven bag – A paper bag is a bag made of paper, usually kraft paper. Paper bags are commonly used as shopping bags, packaging, and sacks. Standard brown paper bags are made from kraft paper. Tote-style paper bags, such as those often used by department stores or as gift bags, can be made from any paper and come in any color. Paper bags can be made from recycled paper, with some local laws requiring bags to have a minimum percentage of post-consumer recycled content. Multiwall (or multi-wall) paper sacks or shipping sacks are often used as shipping containers for bulk materials such as fertilizer, animal feed, sand, dry chemicals, flour, and cement. Many have several layers of sack papers, printed external layers, and inner plies.[9] Some paper sacks have a plastic film, foil, or polyethylene coated paper layer between a water-repellant, insect resistant, or rodent barrier. There are two basic designs of bags: open mouth bags and valve bags. An open mouth bag is a tube of paper plies with the bottom end sealed. The bag is filled through the open mouth and then closed by stitching, adhesive, or tape. Valve sacks have both ends closed and are filled through a valve. A typical example of a valve bag is the cement sack.

No. #12 Removal of Plastic Cap seal

Drum Plastic Cap Seal – it seals the barrels and drums carrying the liquid cargo. Thus, it packs the content of the drums and acts as the essential accessory to protect the content stored inside the Barrels and Drums from adulteration, pilferage, leakage, and evaporation, authenticating the veracity of Quality and Quantity.

Instant Alternative of a Drum Plastic Cap Seal – Drum Capseals can be available in metal elements such as TIN, Mild steel, and aluminum. Drum Capseals have to provide effective Tamper-proofing, Leak resistance, and brand display for the drums. The Inner surface is lacquered to avoid corrosion, and the inner edge has a vinyl gasket for better contact with the flange. Ears and scored lines on these cap seals ensure that the cap seal has to be destroyed before removal so that the cap seals cannot be reused in any manner.

No. #13 Removal of Plastic in Garment Packing

Plastic packaging for Garments: A growing consumer focus on reducing plastics, especially single-use plastic packaging. Hundreds of billions of polybags are estimated to be produced for the fashion industry every year, although it is not precisely known what the scale of the packaging footprint is. However, it forms only a tiny part of the overall impact of a garment lifecycle. The treatment of waste at the end of its use is a vital issue. Even though the plastic currently used – LDPE (low-density polyethylene) is technically recyclable, the recycling rate could be much better. Contaminants such as ink and paper limit the use of the recycled material in many products.

Instant Alternative of Plastic packaging for Garments – Innovative eco-friendly garments packaging by Seaman Paper. It introduces the brand’s inaugural product with this launch Vela bags, a series of transparent paper bags designed to substitute single-use plastic poly bags. Our purpose is to reduce plastic from supply chains.

All mentioned packaging material is easy to implement in the packaging of the product and can get the idea on how to reduce plastic consumption. Primary packaging is not an easy task for the instant removal of packaging material, whatever packaging material is used. On one point, I have mentioned the pharmaceutical plastic blister, but it can be easy to go with Alu – Alu pack and having much more benefits of protection against MVTR and OTR. And on the other point, many companies using stretch wrap in indefinite quantity, which is more harmful than recyclable packaging material. So, I added the plastic in eco-friendly packaging examples.

Read More Article

A sweet story of recycle logo and plastic

Have you imagined why 20gauge is thinner than 16gauge in metal but opposite in plastic film?

How edible packaging material for future sustainable growth?

Pingback: How to explain our Packaging Material specification | PackagingGURUji

Pingback: Top 21 New Sustainable Packaging Innovations so far in 2021

Pingback: First-of-its-kind BPI-Certified Compostable Coffee Pod Lidding Film

Pingback: All-in-One ANTI-COVID display and their packaging - Worldstar Winner 2021 - PackagingGURUji

Pingback: Check out the Top 14 recycling packaging | Paper Packaging Innovations

Hello.

We are exporting safety garments. We are planning to shift to eco-friendly packaging ( see through ).

Please advise.

In India, this option is not available. But we are trying to convince this company to come with their product.

Pingback: Overview on fluorination of HDPE container | Plastic fluorination process

Hi,

We are into corporate gifting services & need safety eco friendly packing products.

I look forward to hearing from you soon.