Find out 9 eco-friendly alternatives to bubble wrap

We all have seen bubble wrap, and how it has changed our life with its easy features. It has been popular for easy availability and made it possible to execute the fundamental parameter to safeguard fragile products. But the 21st century is against the over usage of plastic and also banning single-use plastic. The bubble wrap is used to fill the gap/void between product and container. We need a sustainable alternative to bubble wrap to understand the void with basic features.

What is Void Fill?

Generally, void fill is required for fragile and industrial products because the product dimension is not appropriate for the box and container shape.

So, we utilize the phrase “void fill” or “box filler” to refer to cushioning, padding, or paper cuts you add to your shipping package to protect your goods in transit and form an excellent performance for recipients.

Packaging material is more than just transportation box stuffing. While void fill or box filler is a solution used in corrugated shipping boxes, it is also becoming more common in transport packaging, primarily to add a little “wow” factor to the presentation.

We have numerous options of having different void fillers with plastic and paper material. The unique features of void fill and packaging fillers are special in functionality, aesthetics, sustainability, and different cost in the market. Hereabouts, we outline various options for eco-friendly void fillers.

When we are packaging any fragile product in a container, we are supposed to add it with bubble wrap. Alfred Fielding and Marc Chavannes invented bubble wrap when they discovered a way to seal pockets of air between two plastic shower curtains to create a three-dimensional pattern of tiny bubbles. At the time, they envisioned it would display the next trend in wallpaper styles!

What can I use instead of bubble wrap? Here is the sustainable bubble wrap alternative:

Sr. No. 1 Biodegradable Peanuts Starch

What are biodegradable peanuts made of?

Biodegradable packing peanuts are made from natural, non-toxic sources of corn starch or wheat. It can add the packing material to compost piles. While they are non-toxic or safe if accidentally eaten, the nutritional value has been removed from these items’ starch.

Before the development of biodegradable peanuts, styrofoam peanuts were available. It was developed and patented by Tektronix Inc., And it was made commercially available Circa 1965 by Dow Chemical. First made from 100% virgin polystyrene resin, peanuts made from 100% recycled polystyrene have been commercially feasible since the mid-90s.

The usage is the same as bubble wrap to fill the void in the container or boxes and be the best sustainable alternative to bubble wrap. Many companies give the feasibility open to the consumers, features such as

- The packing peanuts can decompose in water, leaving no toxic waste, and also, it is FDA compliant.

- There is Static-free organic starch.

- It dispenses and vacuums like traditional peanuts.

Biodegradable packing peanuts are made from natural, non-toxic sources, such as wheat and corn starch. It is dissolved in water and can be thrown into compost piles after a single use. Also, biodegradable foam peanuts do not have an electrostatic charge, meaning they will not stick to clothes.

Sr. No. 2 Corrugated bubble

Corrugated Bubbles may be a very eco-friendly option for the voids fillers and substitute for bubble wrap. Many people always on the hunt for greener options and ways to reduce our tread upon the earth. This filler describes the delight of bringing this fantastic product to the marketplace: thrilled beyond belief to share with you EcoEnclose’s green alternative to bubble wrap and foam peanuts! (earlier version – styrofoam)

Recycled Corrugated Bubble’s unique characteristics comprise 100% recycled cardboard made utterly from post-consumer and post-industrial waste. It allows you the option to purchase a Corrugated Bubble made to your exact specifications. Even further, Corrugated Bubble is wholly recyclable & naturally biodegradable.

It’s upcycled recycled!

Sr. No. 3 Bamboo Molded Pulp

Bamboo packaging helps reduce environmental impacts and promotes a healthier planet. Bamboo pulp is just like paper pulp.

This molded pulp comprises the Moso bamboo, Phyllostachys pubescens, and sinocalamus affinisetc, with the sulfate digestion process and soda process.

There are also tender bamboo green, lime pickled into half-clinker—fiber form and length, between wood and grass fiber. Easy sizing, bamboo pulp for medium fiber length pulp, delicate and soft. The pulp thickness is loose, the tear is high, and the breaking strength and tensile strength are low—high mechanical strength.

Paper comprises bamboo pulp, bleached for doing the offset/stamp printing paper, handwritten paper and other advanced paper, unbleached paper for making wrapping paper, etc.

Bamboo pulp paper is made using bamboo pulp alone or with wood pulp and straw pulp in a reasonable proportion through pulping and rinsing, and other paper-making processes.

Sr. No. 4 Recycled Indented Kraft Paper Roll

Besides adding to your product’s aesthetic presentation, the indentations of Indented Kraft Paper are designed to provide a hint of cushioning. Wrap your products in Indented Kraft Paper to protect them against rubbing and scratches in transport. EcoEnclose 100% Recycled Indented Kraft Paper is made entirely from post-consumer & post-industrial content and is recyclable and naturally biodegradable. The 60# paper weight is thick and durable, but the indentations allow this paper to maintain its flexibility to perfectly molding itself around your product.

Sr. No. 5 Starch Foam Sheets

It is a Flexible sheet and wraps around the corners and curves of fragile products as per their shape.

The foam sheet is Static-free. The best part is the property, i.e., it can Biodegrade foam decomposes in water, leaving no waste.

Sr. No. 6 Crinkle Paper

It is an Attractive filler (bubble wrap alternative) for the void for baskets and gift boxes. It is a firmly nestle product with interlocking crinkle-cut paper and a convenient 10 lb. carton UPSable.

Other options available in Paper and Metallic Blends – Add an extra festive touch such as Red, French Vanilla, Forest Green, Black, Lime, Kraft, White, Ivory, and Navy Blue.

See the complete line of Gift Boxes.

Sr. No. 7 Paper Air pillows

AirWave Packaging is breaking new ground in environmental protection and delivers a clear statement on sustainability. The air-cushion chain made of >85% recycled paper is robust and ecologically advantageous. The compostable sealing layer is ultra-thin and therefore does not negatively influence any aspect of recycling. The AirWave PaperWave®-Bio air cushion film has achieved superior environmental benefits.

Easy disposal by the consumer

AirWave PaperWave® has a skinny seal layer made of a starch-based compostable film, which has been confirmed not to affect the paper’s recyclability. The product is 100% recyclable by pulping. The product bears the RESY mark as well as the sorting aid symbol according to DIN 6120. And it makes it very easy for the consumer to decide on the correct recycling bin at their disposal. The material is compostable and even degrades in the water when mistakenly ended there.

Modern technology enables 100% recycling

With today’s repulping technology, the paper and sealant layer will be separated during the recycling process. This enables the new AirWave Paper-Wave® air cushion film to be recycled with the normal wastepaper or the bio-compostable waste.

Sr. No. 8 Mushroom packaging

A well-known biomaterials company, i.e., Evocative and It, produced mushroom packaging utilizing the vegetative part of a mushroom fungus and crop waste to make a bioplastic.

While this might seem funny, large retailers, including Ikea, are counting on using this biodegradable packaging option to substitute polystyrene.

Why? Joanna Yarrow, head of sustainability for Ikea in the UK, has earlier told The Telegraph that several products are packaged in polystyrene, which is either challenging to recycle or cannot be recycled at all.

Consequently, the group is looking for innovative packaging choices, such as fungi packaging. This packaging, which includes mycelium, will normally decompose within weeks, decreasing waste and increasing recycling.

Sr. No. 9 Geami WrapPak Ex

This is a different packaging concept which is a recyclable and biodegradable product that works as a protective cushioning wrap.

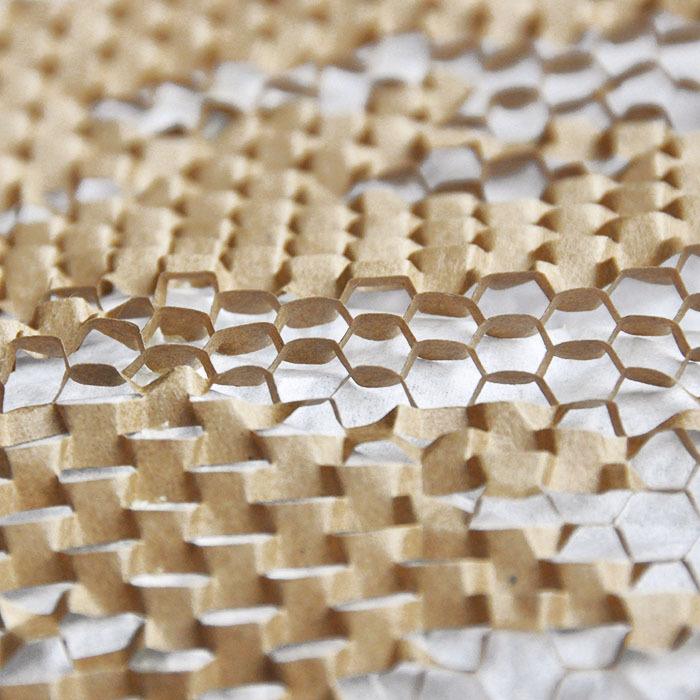

The die-cut 3D honeycomb formation constitutes a cushioning pattern. Geami wrap attains in a convenient dispenser box. And also, it is self-contained, disposable, recyclable: truly retail-ready wrapping.

The Geami WrapPak EX Mini is a convenient dispenser box that extends die-cut kraft paper into a 3D honeycomb construction. Its tiny footprint enables it to be placed on any tabletop or packaging area.

Wrapping is required when pack products need protection against scratching, surface abrasion, and minor handling incidents. WrapPak methods use patented manners to convert environmentally friendly paper into packaging that prevents damage, including difficulties caused by internal consequences when various items are packed together.

Geami WrapPak is a mixture of die-cut kraft paper with tissue interleaf paper. The Geami WrapPak EX Mini expands the die-cut paper to a 3D honeycomb structure giving a unique wrapping product. By locking angled paper cells collectively, items can be wrapped securely without the requirement for adhesive tape or cutting. The converter can be set at any packing station where individual items require a protective wrap.

Read More Article

A sweet story of recycling logo and plastic

Have you imagined why 20gauge is thinner than 16gauge in metal but the opposite in plastic film?

How edible packaging material for future sustainable growth?

Pingback: How to explain our Packaging Material specification | PackagingGURUji