Re-look on corrugated box development in 2019

Every year, we heard the news regarding the advancement in the technology of our product. The improvement is required for our product to give a unique identity, improve stability & compatibility, better performance during transit, and flexibility when production. So, this year, advancements in sustainability, resistance coating, and in their design.

The following are the advancement in the corrugated box this year, 2019.

AcmeGUARD corrugated box: AcmeGUARD has introduced a leading-edge material that gives you an option that delivers a high level of moisture resistance packaging needs. Importantly, you can pack the fruit and vegetables while wet, frozen food, raw meat, and wet containers and cans without concern for damaging the corrugated fibreboard. Also, the coating presents an anti-scuff surface when providing high-quality finishes requiring extra protection during shipping and handling.

AcmeGUARD coating advantages:

- High moisture resistance packaging inside of the corrugated fiberboard

- Feels and behaves like the high-quality box

- Suitable for direct contact food. The food will not stick like Meat, cheese, butter, and other fatty foods.

- It is the replacement of wax-coated materials in many cases, significant cost savings possible.

- Fully recyclable, just like regular box materials

- Both fiber materials are compatible, like Kraft or White liner (outside).

Boron Free Adhesive by Borregaard: Borregaard innovates the glue produced for corrugated fiber boxes without having boron derivatives. Boron derivatives are classified by the European Chemical Agency as Elements of Very High Concern suspected. It can harm fertility, and the unborn child, are appropriated in the glue to make corrugated fiber boxes. Our corrugated fiber box industries don’t have any alternative to this hazardous chemical.

TV screen printing on Bike boxes: The Dutch company has seen damages done to its goods while deliveries drop less 80% after impressing the image of TVs on the boxes of cycle packed.

Possibilities are pretty much everyone knowing this has fallen foul of a package arriving in pretty poor shape. It believed that the information of what is inside a box must assume how a person performs the delivering. If the “fragile” printed over it in big red letters. Although we’d hope our delivery person will take notice and be a little more careful with it. Also, not confirmed to not having the chances of it arriving in one piece.

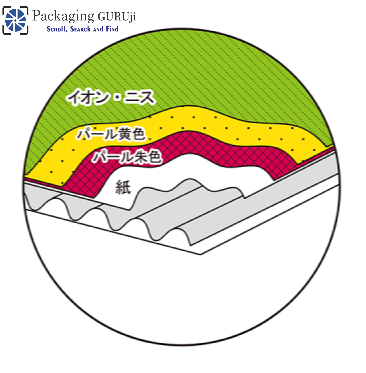

Corrugated box development in 2019 for the freshness retention: One of the Japanese company has developed the base paper coated with uniquely formulated pearl and tourmaline that offers to the advancement of domestic commerce and industry to boost economic development in Japan and overseas.

It has a high freshness holding function, moisture protection, cold and heat retention, rainwater repellency, and cosmetics.

Pingback: How to calculate the loss | Damaged packaging