Everydrop in the container matter to us – Liquiglide

Gripping and squeezing a plastic tube to coax out the last of the toothpaste soon be a distant memory, thankfulness to new technology developed in the US istant LiquiGlide is a chemical manufacturing company based in Cambridge, Massachusetts, has partnered with Colgate to roll out its easy-flowing toothpaste solution.

It is a non-toxic, non-stick coating that can be implemented inside the packaging to eliminating the friction between solids and liquids. This means toothpaste will effortless slide-out, rather than having to be painfully prised out from every last nook and cranny of the tube.

European customers can now try the coating out with Colgates’ the new Elixir line, developed in partnership with the LiquiGlide. Elixir comes in a cleared, recyclable plastic toothpaste package that allowed toothpaste to dispense much more quickly.

the Colgate has just introduced a cleared, recyclable plastic toothpaste package, developed in partnership with LiquiGlide, that allowed toothpaste to dispense complete more quickly (right)

WHAT IS LIQUIGLIDE?

The LiquiGlide is a Cambridge, Massachusetts company founded in 2012 by MIT’s Kripa Varanasi and David Smith.

The firm produces a non-toxic lubricant of the same names. The liquid-impregnated coating acts as a slick barrier within a surface and a viscous liquid.

Implemented inside a condiment bottle, for instance, the coating clings to its sides while allowed the condiment to glide off effectively with no residue.

The firm also designs the coatings to be produced entirely of food, so it is edible and safe for the customer to packaging food-based products.

As well as the partnerships with Colgate and cosmetics firm Mibelle Group, the LiquiGlide has announced its $13.5 million funding round, bringing its total amount raised to $50 million to move out its technology.

Tests so far have been promising that Mibelle Group has reduced the yield loss in its toothpaste manufacturing tanks up to 99 percent, the LiquiGlide claims.

‘Our technology has redefined what is possible when working with thick, slow-moving liquids,’ said Dave Smith, co-founder and CEO at LiquiGlide.

‘We already see its impact with extraordinary breakthroughs in packaging, manufacturing, and the biomedical industries.

‘As we continuing to expand our market presence with our new partnerships with Colgate and the Mibelle Group, we are proud to join forces with global leaders in innovation and customer goods.’

The LiquiGlide has already impressed the consumer packaging company with its video demonstration of ketchup effortless slipped out of a glass bottle and has partnered with other European sauce sellers.

The firm describes its product as ‘the first and only permanently wet, slippery surface technology.’ It is effectively a super-hydrophobic coating, in other words, a thin surface layer that repels water, like a lotus leaf.

The technology combats waste. Much of the product inside the packaging is disposed of because it takes too much effort to extract it on behalf of the consumer.

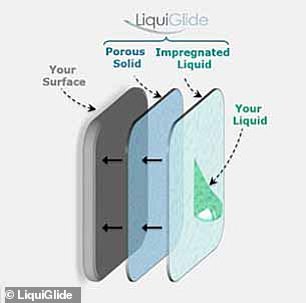

The surface (illustrated) is made up of sufficiently tight spaces to contain the impregnating liquid and keep it in a place.

A lotus leaf is highly hydrophobic and does not absorb water, which means water droplets move around its surface without making it wet. The exterior of a lotus leaf creates a cushion of air for water to sit on, but the LiquiGlide follows this ‘cushion of air with a layer of liquid.

That so-called ‘liquid-impregnated surface’ is a multi-layer surface consisting of a customized permeable solid and a liquid. The solid surface is built up of sufficiently tight spaces to contain the impregnating liquid, and the liquid is held in place to produce a permanently slippery surface.

As a result, toothpaste, ketchup, detergent, and other product slides on the liquid layer in a so-called ‘liquid-to-liquid interface.’

And by adjusting the material used and the coating structure, the researchers can also check the activity at which liquids slide over the surface.

A toothpaste, a special toothpaste nozzle, makes sure it does not just flow out when the tube lid is opened.

Pictured, any droplet of water on a lotus leaf, which has inspired the LiquiGlide coating. The LiquiGlide can be accepted on both plastic and glass containers and can be modified for various applications.

This will ultimately help check product waste, as any residue that ends up in the packaging that is too hard for the customer to extract can end up in the bin.

Every year, an estimated one million tonnes of condiments are thrown away globally because leftovers cannot be abraded from jars and bottles. Up to 15 percent of a product remains in its container.

‘Until now, we have accepted significant waste, whether in manufacturing or packaging, as the portion of the price for these products because they hold to containers or devices they touch,’ said Professor Kripa Varanasi, co-founder and chairman of LiquiGlide.

‘By reducing friction, LiquiGlide’s technology removes this fundamental constraint.

‘Now, we can dispense every last drop, minimize yield loss in manufacturing, and reduce occlusions and infections in medical devices.’

MailOnline has communicated with Colgate regarding its use of the plastics waste crisis and whether it plans to use LiquiGlide with any other types of materials.

Read More Article:

Understanding the criteria for the Bill of Packaging material (BOPM)

How to make our Packaging Material specification?

Complete details about industrial and home composting standards | EN 13432