Top 12 PET Plastic News, Advancements and Discoveries

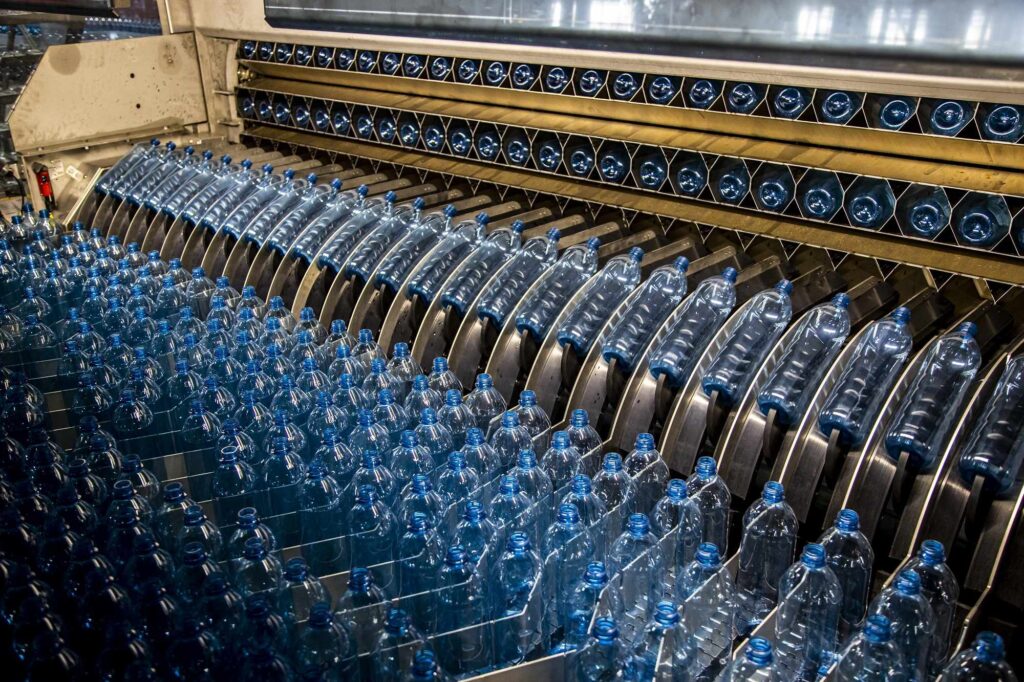

PET plastics are some of the most generally discussed plastic types when seeing drinking water solutions. Polyethylene terephthalate, or PET, is a type of thermoplastic polymer resin regarded as safe and can be seen on water bottles with the number “1”, showing it is a safe option.

The History

John Rex Whinfield, James Tennant Dickson, and others who worked for the company Calico Printers Association initially patented PET plastics in 1941. Once created and found to be highly effective, producing products using PET plastics became more popular. Nathaniel Wyeth patented the first official PET bottle in 1973.

- It has an exceptional level of wear resistance corresponding to other plastics.

- It has an increased flexural modulus.

- It has an exceptional level of stability, making it adaptable and robust.

- Its low friction coefficient makes it useful in different applications other plastics are not.

- The plastic’s chemicals do not leak into the fluid or food stored within it – making it one of the necessary products for food storage.

Now, the Top 12 PET plastic development and discoveries in 2022

1. World’s First Tequila in Paperboard with PET layered ‘Bag-in-Bottle’ Design

Frugalpac creates recycled paper-based products with the lowest carbon footprint, which can be easily recycled and don’t need to go to the landfill. These products are lighter and less bulky than traditional industry methods, meaning they reduce CO2 emissions by comparison. Functionally, a bag-in-box is made by die-cutting and creasing a printed paperboard. Since the format is created without additional labeling or equipment, the rigid bottle is formed from one flat piece of paperboard.

The pouch is then inserted into the mold, which has already had the water-based adhesive used to form it. The Frugal Bottle is made from 94% recycled paperboard and features a metalized PET pouch inside to protect food. It is 5times lighter than a glass bottle and uses less carbon and energy in its production process.

To recycle a plastic food-grade pouch, separate it from the paper bottle and place it in your recycling bin. Or you can put the entire bottle in your paper recycling compartment, and the bag will be easily detached during re-pulping. This process also uses less plastic than using a plastic bottle.

Physical

|

Bottle Type |

Bordeaux |

|

Volume |

750ml (+ 50ml ullage approx) |

|

Liner Pouch |

Dependent on product and shelf life requirements |

|

Bottle Weight |

82g approx |

|

Dimensions |

75mm x 312mm tall detailed drawing available on request |

|

Finish |

Glass Packaging Institute drawing no. 1620 |

|

Closure |

ø30mm x 21mm ROPP |

Performance

|

Bottle Top Load |

>20kg (in ambient conditions 23°C / 45% RH) |

|

Torque Resistance |

>20 lbf-in (in ambient conditions 23°C / 45% RH) |

|

OTR |

Up to 0.0616cc/pack/day available |

|

Shelf Life |

In excess of 12 months with wine. Other products subject to trial |

2. Sidel launches PressureSAFE™, a new safe PET aerosol container

Sidel introduced PressureSAFE™, an innovative PET aerosol container design to support home and personal care brands offering better environmentally sustainable dispensing spray packaging. This newly product packaging solution is authorized for the standard PET recycling stream.

PET dispensing sprays keep the highest product safety standards, exceeding those of aerosol metal containers. PressureSAFE™ supports this innovative design component, which requires the spray’s resistance to pressure to confirm a safe structure and protect against leakages, breakages, and roll-out during transport and storage.

3. Click-It® Patented Closure Technology

Clamshell packaging using Click-It™ Closure technology provides exceptional security with a one-snap closing system that can be opened with just one hand, yet it remains secure in tests such as a penny pitch and wrench toss. It is the only clamshell packaging that does not require scissors, knives, or strength to open, making it easy and accessible for seniors, people with arthritis, and others with mobility challenges.

While Click-It Closure technology is accessible for adults to open, it is remarkable because it can’t be solved by kids, making it a selection for brands that require Certified Child Resistant Packaging. Clamtainer boasts significant financial and sustainability advantages when compared to traditional clamshell packaging. It accepts less time to load and close a Clamtainer, which has substantial pack-out cost advantages for product manufacturers.

Clamainers can be made from various materials, including recycled polyethylene terephthalate (rPET). It makes it a sustainable packaging option, as consumers also reuse it.

4. ALPLA AND VÖSLAUER REDUCE CARBON FOOTPRINT WITH RETURNABLE PET

ALPLA Group has developed a new returnable PET bottle that reduces carbon emissions by around 30 percent and bottle weight by almost 90 percent in comparison to the reusable alternative made of glass. The one-liter bottles are now available in stores.

ALPLA, a resource-conserving company, has created the first modern returnable PET bottle for the Austrian market. This is in addition to Vöslauer’s introduction of a climate-friendly bottle made entirely of recycled PET in 2018.

The bottle, which is made of fully recyclable PET mono-material and has a recycling rate of around 30 percent, will last for three to four years before being recycled again.

5. USING RPET IN THIN-WALL INJECTION MOULDING

In a series of 125 ml transparent, round containers, the in-mold labeling (IML) makes them ready for bottling. The walls are just 0.32 mm thick, making them an option for food products.

The thin-walled containers are made using a single-step process that results in parts with at least 30 percent of rPET. Previously, injection molding was only able to produce thick-wall parts such as bottle preforms. However, the final packaging form is achieved in a second step, for example, by using blow molds.

The European Plastics Pact aims to have all plastic packaging make 30% recycled material by 2025. This means that thin-wall containers made of polyolefins or polystyrene will not be sufficient, and new recycling streams must be developed to meet this goal.

The European Food Safety Authority (EFSA) has also not issued positive assessments for the recycling streams.

6. LanzaTech, with the support of Danone, Discovers a Method to Produce Sustainable PET Bottles from Captured Carbon

A consortium, including LanzaTech and Danone, led to the discovery of a new route to mono ethylene glycol (MEG), a fundamental building block for polyethylene terephthalate (PET), resin, fibers, and bottles. This technology instantly transforms carbon emissions from steel mills or gasified waste biomass into MEG. Carbon capture technology utilizes a proprietary engineered bacterium to convert carbon emissions into MEG.

This method bypasses the requirement for an ethanol intermediate and simplifies the MEG supply chain. The direct production of MEG was confirmed at a laboratory scale, and two external laboratories confirmed the presence of MEG.

This early-stage proof of concept work shows for the first time that it is possible for a bacterium to directly produce MEG from gas. This new technology avoids the multiple processing steps required to convert ethanol into ethylene, ethylene oxide, and MEG.

LanzaTech anticipates that the direct production process will lead to PET bottles and PET fibers with a reduced environmental impact when scaled successfully after a multiyear development phase.

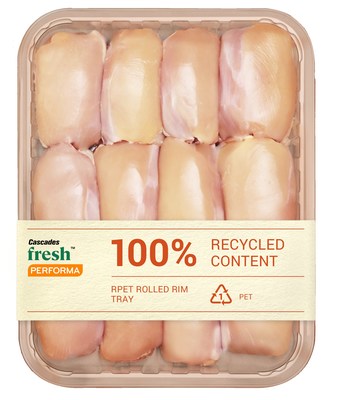

7. Cascades enhances its line of eco-friendly packaging with an innovative recycled material solution

Cascades is proud to announce the development of its eco-friendly packaging line with the expansion of a 100% recycled PET tray. This innovative design creates a perfectly compatible tray with the packaging tools already used by food processors and retailers, making it an ideal choice for sustainable packaging solutions. This tray is made entirely from recycled plastic and has been designed to be as efficient as possible regarding recycling.

This means that not only is the tray itself environmentally friendly, but by using recycled PET products only, Cascades is helping support its consumers in reducing their impact on climate change by 69%. The design of How2Recycle® was started to make it a part of the circular economy, which led to its being prequalified as widely recyclable in Canada and recyclable in limited communities in the United States.

A rolled edge tray made of 100% recycled PET and designed with circular economy in mind. (CNW Group/Cascades Inc.)

The design of this product takes into account how to use the least amount of materials while still providing a rigid structure. Its rolled edges decrease the risk of tearing when using shrink-wrap, preventing food from being wasted.

8. Ring Container Technologies’ New Customizable PET Solution Maintains Carbonation in Beverages, Energy Drinks

Ring Container Technologies announced a customizable PET solution for maintaining carbonation in beverages and energy drinks. This new technology allows beverage manufacturers to create unique, personalized containers that maintain carbonation levels consistently and efficiently.

Customizable energy shots and beverages with BarrierGuard® Enhance™ technology create on-shelf brand differentiation for smaller size carbonated PET bottles.

Enhance can use Ring’s APASS guidance to design an optimal e-commerce solution for carbonated beverages and energy drinks that avoids costly Amazon handling fees. In addition, Enhance bottles are shatterproof and dent resistant, compared to metal cans which may dent during transportation, causing increased retail rejection and inventory cost.

9 Sustainable rigid films for pharmaceutical packaging

The Pentapharm® kpNext™ RB5 barrier film is developed to be recyclable and can be utilized on your existing production lines.

It has the identical thermoforming functionality as traditional packaging material options but is also suitable for liquid products or products with high chemical resistance.

10. Placon OxyStar patented technology for PET material makes oxygen ingress zero

Introducing the world’s first recyclable PET barrier material, OxyStar. Today, the most extensive barrier solutions are classified as a #7 recycling symbol that cannot be recycled. The OxyStar PET barrier material has a #1 recycling symbol, providing the package to be put behind into the PET recycling stream to be used over frequently. Producing a package that gives your products a better way to stay fresher for longer and extends product shelf life while making a sustainable impact is how we make only more suitable packaging.

11. Printex Transparent Packaging is the first manufacturer to make clear boxes with 100% Post-Consumer Recycled (PCR) PET

Printex Transparent Packaging (PTP) has a New clear 100% PCR PET that looks nearly identical to virgin PET and is created from 100% North America-sourced recycled PET plastic.

Until now, PET sheets and film producers have only shown up to 25% and 50% post-consumer recycled content (PCR) plastic for box-grade packaging. Previously, producing a clear and un-tinted PET in 100% PCR was not comfortable. PTP calls their new material Eco-PET 100. It’s a sustainable and replacement for virgin PET.

PCR material is not unexplored, so what is special about our new Eco-PET 100? Earlier, the clarity and quality required for box-grade material were not commercially open in 100% PCR, and to execute that was very costly. The deterrents to its viability were both expensive and aesthetics.

After significant product development and testing, the quality contrast to virgin material is virtually nonexistent to the naked eye. The economics of making this material and getting it to market at a price point that is in line with many businesses packaging budgets needed us to purchase this material in substantial volume.

12. Plastic-eating bacteria to overcome the plastic pollution – Chinese scientists

Chinese specialists say they have recognized a blend of marine bacteria that seems proficient in breaking down polythene, one of the universal plastics on the planet and the origin of much pollution in the world’s oceans.

In the research, which was issued in the Journal of Hazardous Materials on April 23, a unit led by Sun Chaomin said they had found a blend of bacteria that was capable of breaking down not only polyethylene terephthalate (PET) – from which containers are made – but also polyethylene, which is utilized to make woven bags and liners.

The unit said they added bacteria to specimens of PE – polyethylene and polyethylene terephthalate – PET. After repeated experiments, it displayed clear that an appropriate compound of three types of bacteria was causing “apparent damage” to the polythene film, including getting “many heavy cracks and wide holes.”