How GEX Eggshell Bio-Calcium is a game change for the packaging industry: A Tale of Sustainability and Innovation

Calcium carbonate (CaCO3) is a universal additive in the plastics industry.

Why is Calcium carbonate (CaCO3) mixing with the plastic?

It can be added to plastic bags to make them easier to open, and it can be added to any other plastic product to add strength or reduce cost.

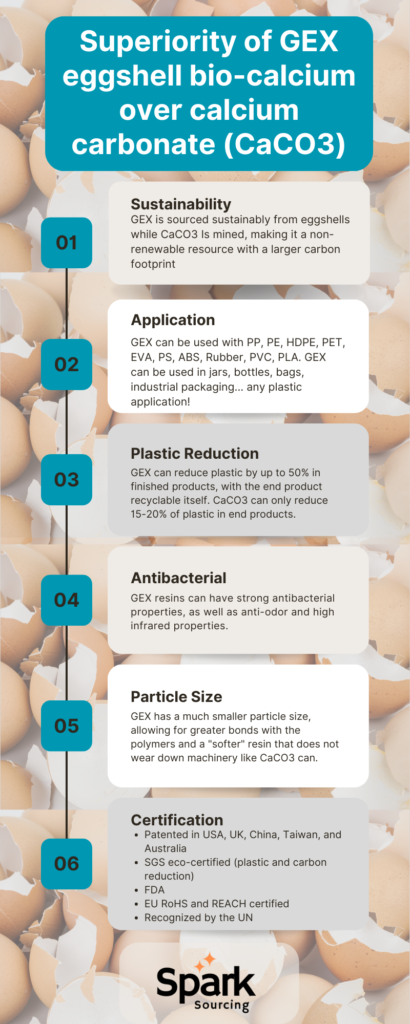

There are some issues with it, however. Even though it can reduce plastic, it, unfortunately, is not eco-friendly. CaCO3 is a mined material with a hefty carbon footprint. Factories, then, cannot say that they are being green by using it to reduce plastic content.

Q&A: How do we calculate the Calcium carbonate in the plastic?

A: Ash Content Method

Another problem with Calcium carbonate

It is incompatible with all plastics and doesn’t bind well with others, making the end product quality relatively poor. Manufacturers also don’t care for the additive as it can tear up their expensive machines because it is a hard mineral.

During our extensive exploration of calcium carbonate (CaCO3), a revelation awaited us – the enchanting bio-calcium carbonate extracted from oyster shells. As a biological derivative of calcium, this extraordinary substance presented a manifold increase in interfacial interactions with plastic polymers when introduced to plastic matrices.

This intricate interplay engendered an unparalleled product quality capable of effectuating an astonishing plastic reduction of up to 50%. Notably, the bio-calcium carbonate showcased remarkable compatibility with various plastic substrates. Yet, the grandeur of its attributes didn’t cease there – products fashioned from this unique material exhibited a distinctive facet: an inherent resistance to bacterial proliferation.

Perhaps the crowning virtue of this innovation lay in its provenance – a wellspring of sustainability. Sourced from a renewable and eco-friendly reservoir, this bio-calcium carbonate assumed the role of a potent catalyst in shrinking one’s carbon footprint.

However, a duo of challenges persisted. Firstly, the material retained its formidable tenacity, potentially exerting excessive strain on industrial machinery. Secondly, the finite supply of oysters worldwide posed an inherent constraint to its widespread utilization.

GEX – bio-calcium

GEX, a bio-calcium sourced from chicken eggs (or other poultry), turned into a plastic-reduction wonder material through a patented process. The egg particles are even smaller (making better products) and softer (not harming machines). The material can still reduce plastic by up to 50%, produce anti-bacterial end products, and be used with recycled plastics to make 100% virgin plastic-free products much lower in total plastic. When used with recycled plastic, it can reduce carbon emissions by nearly 70% compared to virgin plastics.

Patented GEX eggshell bio-calcium

GEX eggshell bio-calcium is patented in the USA, UK, Australia, China, and Taiwan, and it has been certified by SGS as a carbon and plastic reducer. It means companies can use it to make greener packaging, and they can receive eco-certification as well. It can also help companies efficiently and quickly meet plastic-reduction mandates, something calcium carbonate cannot do. It is easy for manufacturers to work with, and they can cut a quick 25-50% off of their plastic use without redesigning a bottle or tray, reducing the size of their packaging, or finding a brand-new material. They must mix GEX into their compound to immediately reduce their plastic use and reduce their carbon footprint.

Game-changing Applications

GEX eggshell bio-calcium is the solution we chose to champion, and we are fortunate to be authorized distributors and representatives of the material. Here are some of the solutions that we have seen made possible:

- Pharmaceutical bottles made from 30% GEX + 70% rHDPE (receiving commendation from the UN for plastic reduction along with their SDGs)

- Cosmetic jars and tubes made from 30% GEX and 70%PP (and 70% rPP)

- Foam mats and gym flooring that are 40% less plastic, cheaper, and anti-bacterial

- Trays and industrial packaging with 50% GEX

- Bags (for DELL and HP) are made from 50% GEX and 50% recycled plastic.

- GEX + PLA for reduced plastic and biodegradable straws, utensils, etc.

- Industrial buckets, bins, and barriers with a 30% plastic reduction.

- Pallets made of recycled plastic and GEX that pass stringent strength tests.

- And lots more…