Patented PHA Technology to a New Food Product Packaging – CJ Biomaterials, Inc.

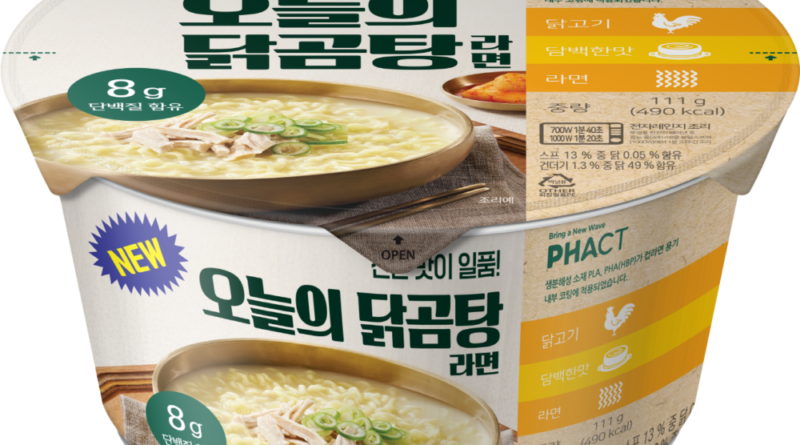

CJ Biomaterials, Inc., a subsidiary of South Korea’s CJ CheilJedang and a significant manufacturer of polyhydroxyalkanoate (PHA) biopolymers, has announced that its patented PHA technology is being utilized in the manufacturing of a new noodle cup available at South Korea’s top convenience store chain, CU.

The unique, eco-friendly noodle cup is the first of its kind in the country. With CJ Biomaterials’ PHA technology incorporated into the cups’ inner coating, they are biodegradable and compostable, decreasing plastic waste entering the atmosphere.

In 2023, CJ Biomaterials designed microwavable paper coating technology, incorporating its patented PHA with PLA. The paper coating solution increases bio-based content, lowering petroleum-based plastic use without compromising the use and quality of the paper cup.

The coating technology will be used on the convenience store’s popular New Today’s Chicken Noodle cup packaging through CJ Biomaterials’ partnership with CU.

“Using PHA with PLA can improve the processibility of PLA by delivering flexibility and letting more stable use across a wide range of temperatures. It even exhibits good oil barrier properties, surpassing conventional polypropylene coating while delivering a 100% biobased solution,” says Max Senechal, Executive Vice President and Chief Commercial Officer at CJ Biomaterials.

“Through this partnership with CU, we contribute to creating eco-friendly packaging and demonstrating the practicality and affordability of sustainable alternatives. It marks a significant step toward reducing plastic waste and promoting a greener, more environmentally responsible future.”

CJ Biomaterials’ PHA biopolymers are derived from nature and produced sustainably. It can be used as building blocks to replace and improve the functional characteristics of a broad range of polymers in producing finished goods or as starting points for sustainable chemistry. PHAs work well as modifiers to other polymers or biopolymers and can increase bio-based content, accelerate biodegradation, and improve the functional properties of resins and finished products. As one of only a few companies capable of mass-producing PHA, CJ Biomaterials is committed to impactful action, delivering eco-friendly solutions with its extensive PHA technology platform.

CJ Biomaterials continues to expand on the applications of its PHA technology, developing solutions for food and beverage packaging, food service ware, fibers and nonwovens, consumer goods, agriculture and horticulture, and 3D printing filament. Over the past year, the company worked together with RIMAN INCELLDERM to create environmentally friendly cosmetic packaging and collaborated with various companies, including CJ Olive Young, Dongil Platech, Yuhan-Kimberly, Banila Co, and biopolymer manufacturer NatureWorks, to broaden the use of PHA in multiple markets and applications. The company also won the German 2023 Red Dot Design Award for the PHA Head-Up Toothbrush, developed in partnership with eco-friendly design specialist Revelop.